RCF HDL 6-A Layin Array Module

Bayanin samfur

Ƙayyadaddun bayanai:

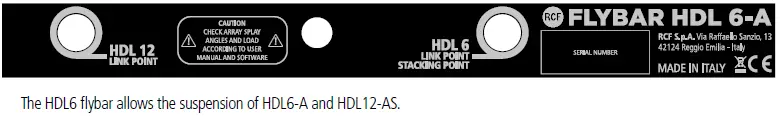

- Samfura: HDL 6-A HDL 12-AS

- Nau'in: Module Tsararrun Layi Mai Aiki, Module Array Subwoofer Mai Aiki

- Ayyukan Farko: Matakan matsa lamba mai girma, madaidaiciyar kai tsaye, ingancin sauti

- Siffofin: Rage nauyi, sauƙin amfani

Umarnin Amfani da samfur

Gabaɗaya Umarnin Tsaro da Gargaɗi:

MUHIMMAN NOTE:

Kafin amfani da tsarin, karanta a hankali littafin koyarwa da aka bayar. Yana da mahimmanci don shigarwa daidai da amfani mai aminci. Koyaushe kiyaye littafin don tunani na gaba.

GARGAƊI – TSORON TSIRA:

- Karanta duk matakan tsaro a hankali saboda suna ɗauke da mahimman bayanai.

- Kauce wa kowane abu ko ruwa daga shigar da samfurin don hana gajerun kewayawa.

- Kada kayi ƙoƙarin kowane gyare-gyaren da ba'a dalla-dalla a cikin littafin. Tuntuɓi ma'aikatan sabis masu izini don kowace matsala.

- Cire haɗin kebul na wutar lantarki idan samfurin ba a yi amfani da shi na tsawon lokaci ba.

- Idan an gano sabon wari ko hayaki, kashe samfurin nan da nan.

- Tabbatar masu sakawa ƙwararru suna ɗaukar shigarwar don bin ƙa'idodi da ƙa'idodi.

Bayanin Girkawa:

- Yi amfani da madaidaitan wuraren da aka keɓe don dakatarwar shigarwa.

- Bincika dacewar saman goyan baya kuma yi amfani da abubuwan da suka dace don haɗewa.

- Guji tara raka'a da yawa sai dai idan an ƙayyade a cikin littafin mai amfani don hana faɗuwar kayan aiki.

Tambayoyin da ake yawan yi

Tambaya: Ta yaya zan adana samfurin idan ba a yi amfani da shi ba na tsawon lokaci?

A: Ana ba da shawarar cire haɗin kebul na wutar lantarki idan ba a yi amfani da samfur na dogon lokaci don tabbatar da aminci ba.

Tambaya: Zan iya gyara ko gyara samfurin da kaina?

A: A'a, an ba da shawarar kada a gudanar da wani aiki, gyare-gyare, ko gyare-gyaren da ba a yi cikakken bayani a cikin littafin ba. Tuntuɓi ma'aikatan sabis masu izini don kowace matsala.

Tambaya: Zan iya tara raka'a da yawa na wannan samfurin?

A: Don hana faɗuwar kayan aiki kasada, guje wa tara raka'a da yawa sai dai in an ambata musamman a cikin littafin jagorar mai amfani.

GABATARWA

Bukatun tsarin ƙarfafa sauti na zamani sun fi girma fiye da da. Bayan aiki mai tsabta - matakan matsin lamba mai girma, madaidaiciyar madaidaiciyar kai tsaye, da ingancin sauti sauran fannoni suna da mahimmanci ga kamfanonin haya da samar da kayayyaki kamar rage nauyi da sauƙin amfani don haɓaka jigilar kayayyaki da lokaci. HDL 6-A yana canza ra'ayi na manyan tsararrun tsararru, yana ba da wasan kwaikwayo na farko zuwa faɗaɗa kasuwar ƙwararrun masu amfani.

JAMA'AR TSIRA DA GARGADI

MUHIMMAN NOTE

Kafin haɗa ta amfani da ko rigging na tsarin, da fatan za a karanta wannan jagorar a hankali kuma ajiye shi a hannu don tunani na gaba. Ya kamata a ɗauki littafin a matsayin wani ɓangaren samfurin

kuma dole ne ya bi tsarin lokacin da ya canza ikon mallaka a matsayin maƙasudin shigarwa daidai da amfani da kuma kiyaye tsaro. RCF SpA ba zai ɗauki kowane alhakin shigarwa da/ko amfani da samfurin ba daidai ba.

GARGADI

- Don hana haɗarin gobara ko girgiza wutar lantarki, kar a taɓa saka wannan kayan ga ruwan sama ko zafi.

- Tsarin layin TT+ ya kamata a rikitar da shi kuma ya gudana ta ƙwararrun ƙwararrun ƙwararrun ma'aikata ko ma'aikatan da aka horar da su ƙarƙashin kulawar ƙwararrun ƙwararru.

- Kafin yin magudin tsarin a hankali karanta wannan jagorar.

KIYAYEN TSIRA

- Dole ne a karanta dukkan matakan tsaro, musamman na tsaro da kulawa ta musamman, saboda suna ba da mahimman bayanai.

- Samar da wutar lantarki daga mains

- Mains voltage yana da isasshen girma don haɗa haɗarin lantarki; shigar da haɗa wannan samfurin kafin shigar da shi a ciki. Kafin kunna wutar lantarki, tabbatar da cewa an yi duk haɗin gwiwar daidai da vol.tage na mains ɗin ku yayi daidai da voltage wanda aka nuna akan farantin kima akan naúrar, idan ba haka ba, da fatan za a tuntuɓi dilan RCF ɗin ku.

- Abubuwan ƙarfe na naúrar suna ƙasa ta hanyar kebul na wutar lantarki. Na'urar da ke da CLASS I za a haɗa ta zuwa madaidaicin soket tare da haɗin ƙasa mai karewa.

- Kare kebul na wutar lantarki daga lalacewa; a tabbata an sanya shi ta hanyar da ba za a iya taka ta ko murkushe shi da abubuwa ba. Don hana haɗarin girgiza wutar lantarki, taɓa buɗe wannan samfur: babu sassan ciki waɗanda mai amfani ke buƙatar shiga.

- Tabbatar cewa babu wani abu ko ruwa da zai iya shiga cikin wannan samfurin, saboda wannan na iya haifar da gajeriyar da'ira.

Wannan na'urar kada ta kasance a fallasa ga ɗigowa ko fantsama. Babu wani abu da ke cike da ruwa, kamar vases, da za a sanya a wannan na'ura. Kada a sanya tushe tsirara (kamar kyandir masu haske) akan wannan na'urar. - Kar a taɓa yin ƙoƙarin aiwatar da kowane ayyuka, gyare-gyare ko gyare-gyare waɗanda ba a bayyana su ba a cikin wannan jagorar.

Tuntuɓi cibiyar sabis ɗin ku mai izini ko ƙwararrun ma'aikata idan ɗayan waɗannan abubuwan sun faru:- samfurin baya aiki (ko yana aiki ta hanya mara kyau).

- Kebul na wutar lantarki ya lalace.

- Abubuwa ko ruwaye sun shiga cikin naúrar.

- Samfurin ya kasance ƙarƙashin tasiri mai nauyi.

- Idan ba a yi amfani da wannan samfur na dogon lokaci ba, cire haɗin kebul na wutar lantarki.

- Idan wannan samfur ya fara fitar da duk wani ƙanshin hayaƙi ko hayaƙi, kashe shi nan da nan kuma cire haɗin kebul ɗin wutar.

- Kada ka haɗa wannan samfurin zuwa kowane kayan aiki ko na'urorin haɗi waɗanda ba a hango ba.

Don dakatar da shigarwa, yi amfani da wuraren da aka keɓe kawai, kuma kar a yi ƙoƙarin rataya wannan samfurin ta amfani da abubuwan da basu dace ba ko kuma ba takamaiman don wannan dalili ba. Hakanan duba dacewar saman goyan bayan da aka ɗora samfurin (bango, rufi, tsari, da sauransu), da kuma abubuwan da ake amfani da su don haɗe-haɗe (anchors, screws, brackets ba RCF ba, da sauransu), waɗanda dole ne su ba da garanti. tsaro na tsarin / shigarwa akan lokaci, kuma la'akari, don exampHar ila yau, girgizar injin da aka saba haifar ta hanyar transducers. Don hana haɗarin faɗuwar kayan aiki, kar a tara raka'a da yawa na wannan samfurin sai dai idan an fayyace wannan yuwuwar a cikin littafin mai amfani. - RCF SpA tana ba da shawarar cewa an shigar da wannan samfurin ta ƙwararrun ƙwararrun masu sakawa (ko kamfanoni na musamman) waɗanda za su iya tabbatar da shigarwa daidai da tabbatar da shi bisa ga ƙa'idodin da ke aiki.

Duk tsarin sauti dole ne ya bi ƙa'idodi da ƙa'idodi game da tsarin lantarki. - Taimako da trolleys.

Ya kamata a yi amfani da kayan aikin akan trolleys ko goyan baya, inda ya cancanta, waɗanda masana'anta suka ba da shawarar. Dole ne a motsa kayan aiki/tallafi/ taro na trolley tare da taka tsantsan. Tsaya kwatsam, ƙarfin turawa da yawa, da benaye marasa daidaituwa na iya sa taron ya juye. - Akwai abubuwa da yawa na inji da na lantarki da za a yi la'akari da su lokacin shigar da tsarin sauti na ƙwararru (ban da waɗanda ke da tsayayyen sauti, kamar matsin sauti, kusurwar ɗaukar hoto, amsa mitar, da sauransu).

- Rashin ji.

Fitarwa ga matakan sauti masu girma na iya haifar da asarar ji na dindindin. Matsayin ƙarar sauti wanda ke haifar da asarar ji ya bambanta da mutum zuwa mutum kuma ya dogara da tsawon lokacin bayyanarwa. Don hana yiwuwar kamuwa da haɗari ga matakan ƙarar sauti, duk wanda aka fallasa ga waɗannan matakan ya kamata ya yi amfani da isassun na'urorin kariya. Lokacin da ake amfani da transducer mai iya samar da matakan sauti masu girma, don haka ya zama dole a sa matosai ko belun kunne masu kariya. Dubi ƙayyadaddun fasaha na hannu don sanin matsakaicin matakin matsi na sauti.

Don hana faruwar hayaniya akan igiyoyin siginar layi, yi amfani da igiyoyin da aka tantance kawai kuma a guji sanya su kusa da:

- Kayan aikin da ke samar da filaye masu ƙarfi na lantarki.

- Wutar lantarki

- Layukan lasifikar.

KARFIN AIKI

- Sanya wannan samfurin nesa da kowane tushen zafi kuma koyaushe tabbatar da isasshen iska kewaye da shi.

- Kar a yi lodin wannan samfur na dogon lokaci.

- Kada a tilasta abubuwan sarrafawa (maɓallan, ƙwanƙwasa, da sauransu).

- Kada a yi amfani da kaushi, barasa, benzene, ko wasu abubuwa masu lalacewa don tsaftace sassan wannan samfurin.

HANKALI

Don hana haɗarin girgiza wutar lantarki, kar a haɗa da wutar lantarki ta hanyar sadarwa yayin da ake cire mashin ɗin.

GABAN TSARE AIKI

- Kar a hana matattarar samun iska na naúrar. Sanya wannan samfur mai nisa daga kowane tushen zafi kuma koyaushe tabbatar da isasshiyar zagayawa a kusa da ma'aunin samun iska.

- Kar a yi lodin wannan samfurin na tsawon lokaci mai tsawo.

- Kada a taɓa tilasta abubuwan sarrafawa (maɓallai, ƙugiya, da sauransu).

- Kada a yi amfani da kaushi, barasa, benzene, ko wasu abubuwa masu lalacewa don tsaftace sassan wannan samfurin.

HDL 6-A

- HDL 6-A shine babban iko mai ƙarfi na gaske wanda aka shirya don amfani da balaguron balaguro don ƙananan al'amura masu girma zuwa matsakaici, a ciki da waje. An sanye shi da 2 x 6 "woofers, da direbobi 1.7", yana ba da ingantaccen ingancin sake kunnawa da matakan matsa lamba mai ƙarfi tare da ginanniyar 1400W mai ƙarfi na dijital. amplifier wanda ke ba da mafi girman SPL yayin rage buƙatun makamashi.

- Kowane bangare, daga wutar lantarki zuwa allon shigarwa tare da DSP, zuwa fitarwa stages to woofers da drivers, an akai-akai kuma musamman ta RCF ta gogaggen injiniyoyi teams, tare da duk sassa a hankali daidaita da juna.

- Wannan cikakken haɗin kai na duk abubuwan haɗin gwiwa yana ba da damar yin aiki mafi girma kawai da matsakaicin amincin aiki amma kuma yana ba masu amfani da sauƙin kulawa da toshe-da-wasa ta'aziyya.

- Bayan wannan muhimmiyar hujja, masu magana da aiki suna ba da advan mai mahimmancitages: yayin da masu magana da yawa sukan buƙaci dogon kebul na gudana, asarar makamashi saboda juriya na kebul shine babban al'amari. Ba a ganin wannan tasirin a cikin lasifikan da aka yi amfani da su a inda amplifier yana da nisan santimita biyu kacal daga transducer.

- Yin amfani da ci-gaba na neodymium maganadiso da sabon gida mai ban sha'awa wanda aka gina daga plywood mara nauyi da polypropylene, yana da ƙarancin nauyi na ban mamaki don sauƙin sarrafawa da tashi.

- HDL 6-A shine mafi kyawun zaɓi lokacin da ake buƙatar aikin tsararrun layi da saiti mai sauri da sauƙi dole. Tsarin ya ƙunshi masu fassara na zamani na RCF; babban direban muryar muryoyin murya mai ƙarfi 1.7 ″ wanda aka ɗora akan madaidaicin 100° x 10° waveguide yana isar da tsayuwar murya tare da babban ma'ana da ƙarfi mai ban mamaki.

HDL 12-AS

- HDL 12-AS shine abokin subwoofer na HDL 6-A. Gidajen woofer 12 ″, HDL 12-AS, ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan shinge ne kuma yana fasalta dijital mai ƙarfi na 1400 W. amplififi. Yana da manufa mai dacewa don ƙirƙirar HDL mai tashi

- 6-Kungiyoyi masu ban mamaki. Godiya ga ƙaƙƙarfan girmansa ana iya ɗauka cikin sauƙi kuma yana da sauri da sauƙi don fara amfani da ginanniyar sitiriyo crossover (DSP) tare da mitar giciye mai daidaitawa don haɗa tsarin tsararrun layin.

- Yana fasalta ginin sitiriyo na sitiriyo na dijital (DSP) tare da mitar giciye mai daidaitawa don haɗa layin tsararrun layin HDL 6-A ko tauraron dan adam.

- Makanikai masu haɗaka duka biyu masu sauri ne kuma abin dogaro. Gilashin gaba mai nauyi mai nauyi yana da ƙarfi. Kumfa mai fayyace-zuwa-sauti na musamman da ke goyan baya a ciki yana taimakawa ƙarin kariya na masu juyawa daga ƙura.

ABUBUWAN WUTA DA SATA

GARGADI

- An tsara tsarin don yin aiki a cikin maƙiya da yanayi masu buƙata. Duk da haka, yana da mahimmanci a kula da wutar lantarki ta AC kuma saita rarraba wutar lantarki mai kyau.

- An tsara tsarin don zama GROUNDE. Yi amfani da haɗin ƙasa koyaushe.

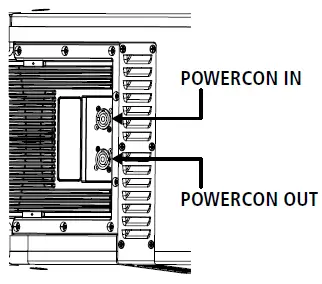

- PowerCon appliancer na'urar cire haɗin wutar lantarki ce ta hanyar AC kuma dole ne a iya samun sauƙin shiga yayin da bayan shigarwa.

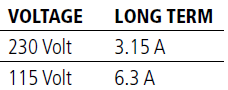

YANZU

Masu zuwa sune buƙatun dogon lokaci da kololuwar buƙatun ga kowane samfurin HDL 6-A/HDL12-AS:

Ana samun jimillar abin da ake buƙata na yanzu ta hanyar ninka buƙatun yanzu guda ɗaya ta adadin kayayyaki. Don samun mafi kyawun aiki tabbatar da cewa jimillar fashe buƙatun tsarin baya haifar da mahimmin voltage sauke a kan igiyoyi.

GASKIYA

Tabbatar cewa duk tsarin yana ƙasa da kyau. Duk wuraren da aka kafa ƙasa za a haɗa su da kumburin ƙasa ɗaya. Wannan zai inganta rage hums a cikin tsarin sauti.

AC CABLES DAISY CAINS

Ana ba da kowane nau'in HDL 6-A/HDL12-AS tare da tashar Powercon zuwa sarkar daisy sauran kayayyaki. Matsakaicin adadin kayayyaki da zai yiwu ga sarkar daisy shine:

- 230 Volt: 6 modules duka

- 115 Volt: 3 modules duka

GARGAƊI – HADARIN WUTA

Mafi girman adadin samfura a cikin sarkar daisy za su wuce matsakaicin ma'aunin mai haɗa Powercon kuma ya haifar da yanayi mai yuwuwar haɗari.

WUTA DAGA HANKALI UKU

Lokacin da aka kunna tsarin daga rarraba wutar lantarki na matakai uku yana da matukar mahimmanci don kiyaye ma'auni mai kyau a cikin nauyin kowane lokaci na ikon AC. Yana da matukar muhimmanci a haɗa subwoofers da tauraron dan adam a cikin lissafin rarraba wutar lantarki: duka subwoofers da tauraron dan adam za a rarraba tsakanin matakai uku.

RIGGING DA TSARIN

RCF ta haɓaka cikakkiyar hanya don saitawa da rataye tsarin tsararrun layi na HDL 6-A wanda ya fara daga bayanan software, shinge, riging, na'urorin haɗi, da igiyoyi, har zuwa shigarwa na ƙarshe.

GARGAƊI NA GWAMNATIN RIGGING DA KIYAYEN TSIRA

- Dakatar da lodi ya kamata a yi tare da taka tsantsan.

- Lokacin tura tsarin koyaushe sanya kwalkwali da takalma masu kariya.

- Kada ka ƙyale mutane su wuce ƙarƙashin tsarin yayin aikin shigarwa.

- Kar a taɓa barin tsarin ba tare da kulawa ba yayin aikin shigarwa.

- Kada a taɓa shigar da tsarin akan wuraren samun damar jama'a.

- Kada a taɓa haɗa wasu lodi zuwa tsarin tsararru.

- Kada a taɓa hawan tsarin yayin ko bayan shigarwa.

- Kada a taba bijirar da tsarin zuwa ƙarin lodin da iska ko dusar ƙanƙara suka ƙirƙira.

GARGADI

- Dole ne a yi magudin tsarin da dokoki da ka'idojin Kasar da ake amfani da tsarin. Hakki ne na mai shi ko damfara don tabbatar da cewa an tafka magudin tsarin a kowace kasa da dokoki da ka'idoji.

- Koyaushe bincika cewa duk sassan tsarin rigging waɗanda ba a samar da su daga RCF ba sune:

- dace da aikace-aikace

- yarda, bokan, da kuma alama

- yadda ya kamata

- cikin cikakkiyar yanayi

- Kowace hukuma tana goyan bayan cikakken nauyin ɓangaren tsarin da ke ƙasa. Dole ne a duba kowace majalisar ministocin tsarin da kyau.

RCF SIFFOFIN AZZAN SOFTWARE DA BANGAREN TSIRA

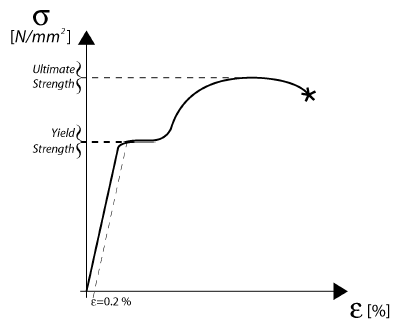

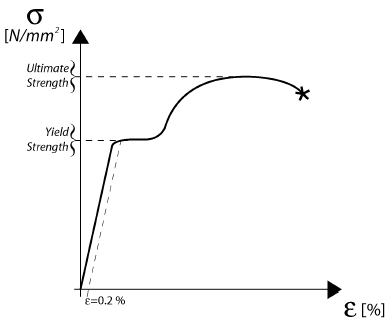

An ƙera tsarin dakatarwa don samun ingantaccen yanayin tsaro (dangane da daidaitawa). Yin amfani da software na "HDL50 Siffar Designer" yana da sauƙin fahimtar abubuwan aminci da iyaka ga kowane ƙayyadaddun tsari. Don ƙarin fahimtar abin da kewayon aminci da injiniyoyi ke aiki ana buƙatar gabatarwa mai sauƙi: HDL 6-A kayan aikin injiniyoyi an gina su tare da UNI EN 10025 Karfe. Software na Hasashen RCF yana ƙididdige ƙarfi akan kowane ɓangaren da aka danne na taron kuma yana nuna ƙarancin aminci ga kowane hanyar haɗi. Ƙarfe na tsari yana da ƙugiya-damuwa (ko daidai Ƙarfin Ƙarfi) mai lankwasa kamar haka:

An siffanta lanƙwan da maki biyu masu mahimmanci: Ƙirar Hutu da Ƙimar Haɓaka. Matsakaicin matsi na ƙarshe shine kawai matsakaicin matsakaicin da aka samu. Ana amfani da matsanancin damuwa na ƙarshe azaman ma'auni na ƙarfin kayan don ƙirar tsari, amma ya kamata a gane cewa sauran kaddarorin ƙarfi na iya zama mafi mahimmanci. Ɗayan waɗannan tabbas shine Ƙarfin Haɓaka. Zane-zane na damuwa-ƙarfe na tsarin ƙarfe yana nuna kayyadaddun hutu a cikin matsi ƙasa da ƙarfin ƙarshe. A wannan mawuyacin hali, kayan yana haɓaka da yawa ba tare da wani canji a cikin damuwa ba. Damuwar da hakan ke faruwa ana kiranta da Matsayin Haɓaka. Nakasawa na dindindin na iya zama mai lahani, kuma masana'antar ta karɓi nau'in filastik 0.2% a matsayin iyaka na sabani wanda duk hukumomin gudanarwa ke ɗaukan karɓuwa. Don tashin hankali da matsawa, madaidaicin danniya a wannan nau'in daidaitawa ana bayyana shi azaman yawan amfanin ƙasa.

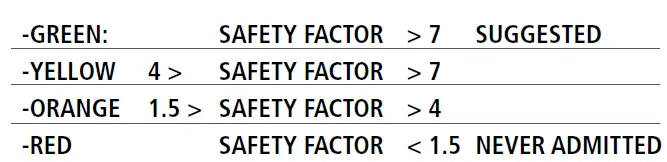

- A cikin software na tsinkayar mu, ana ƙididdige Abubuwan Tsaro idan aka yi la'akari da Matsakaicin Matsakaicin Ƙarfin Hasashen, bisa ga ƙa'idodi da ƙa'idodi na duniya da yawa.

- Sakamakon Safety Factor shine mafi ƙarancin duk abubuwan aminci da aka ƙididdige, don kowane hanyar haɗi ko fil.

Wannan shine inda kake aiki tare da SF=7

- Dangane da ƙa'idodin aminci na gida da halin da ake ciki, abin da ake buƙata na aminci zai iya bambanta. Hakki ne na mai shi ko damfara don tabbatar da cewa tsarin ya yi daidai da dokokin ƙasa da na gida.

- Software na "RCF Siffar Designer" yana ba da cikakkun bayanai game da yanayin aminci ga kowane ƙayyadaddun tsari.

- An rarraba sakamakon zuwa aji hudu:

GARGADI

- Dalili na aminci shine sakamakon sojojin da ke aiki akan sandunan gardama da tsarin gaba da na baya da kuma fil kuma ya dogara da masu canji da yawa:

- – adadin kabad

– tashi mashaya kwana

- kusurwoyi daga kabad zuwa kabad. Idan ɗaya daga cikin sauye-sauyen da aka ambata ya canza yanayin aminci dole ne a sake ƙididdige shi ta amfani da software kafin rigingimun tsarin.

- – adadin kabad

- Idan an ɗauko sandar gardawa daga injina 2 a tabbata cewa kusurwar sandar gardama daidai ne. Kusurwar da ta bambanta da kusurwar da aka yi amfani da ita a cikin software na tsinkaya na iya zama mai haɗari. Kada ka ƙyale mutane su tsaya ko wucewa ƙarƙashin tsarin yayin aikin shigarwa.

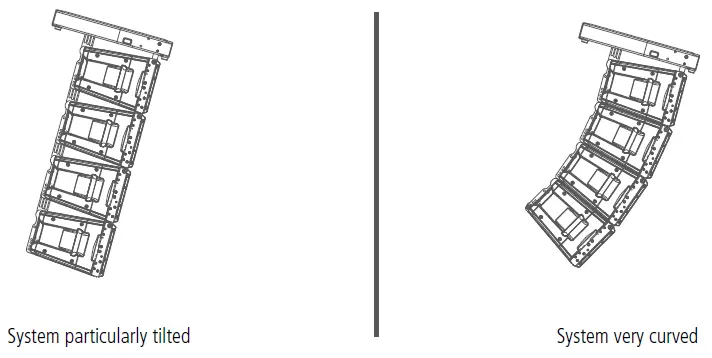

- Lokacin da shingen gardama ya karkata musamman ko tsararru tana lanƙwasa sosai tsakiyar nauyi na iya fita daga hanyoyin haɗin baya. A wannan yanayin, hanyoyin haɗin gaba suna cikin matsawa kuma hanyoyin haɗin baya suna tallafawa jimlar nauyin tsarin tare da matsawa gaba. Koyaushe bincika a hankali tare da software na "HDL 6-A Siffar Designer" don duk waɗannan nau'ikan yanayi (har ma da ƙaramin adadin kabad).

HASASHE SOFTWARE - MAI SIFFOFIN SIFFOFIN

- HDL 6-A Siffar Designer software ce ta wucin gadi, mai amfani ga saitin tsararru, don injiniyoyi, da shawarwarin saiti masu dacewa.

- Mafi kyawun saitin jeri na lasifikar ba zai iya yin watsi da abubuwan da suka dace na acoustics da sanin cewa abubuwa da yawa suna ba da gudummawa ga sakamakon sauti wanda ya dace da tsammanin. RCF tana ba mai amfani da kayan aiki masu sauƙi waɗanda ke taimakawa saitin tsarin cikin sauƙi da dogaro.

- Nan ba da jimawa ba za a maye gurbin wannan software da cikakkiyar software don tsararraki da yawa da hadaddun simintin wuri tare da taswira da jadawalin sakamakon.

- RCF tana ba da shawarar yin amfani da wannan software don kowane nau'in daidaitawar HDL 6-A.

SHIGA SOFTWARE

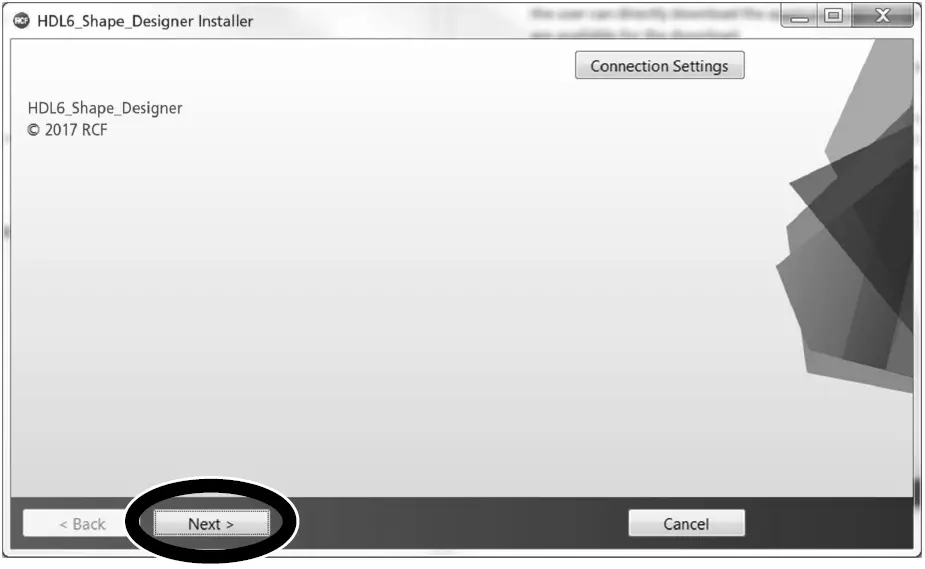

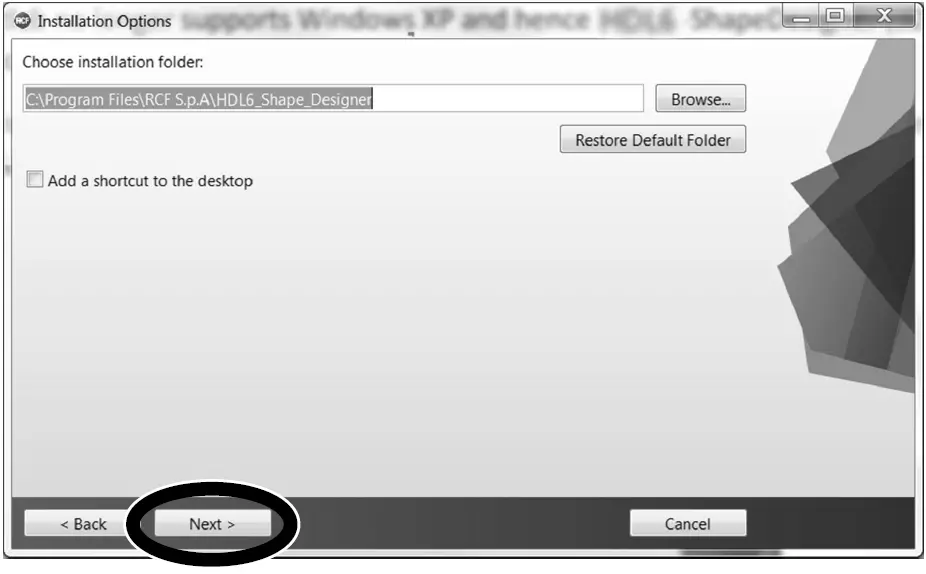

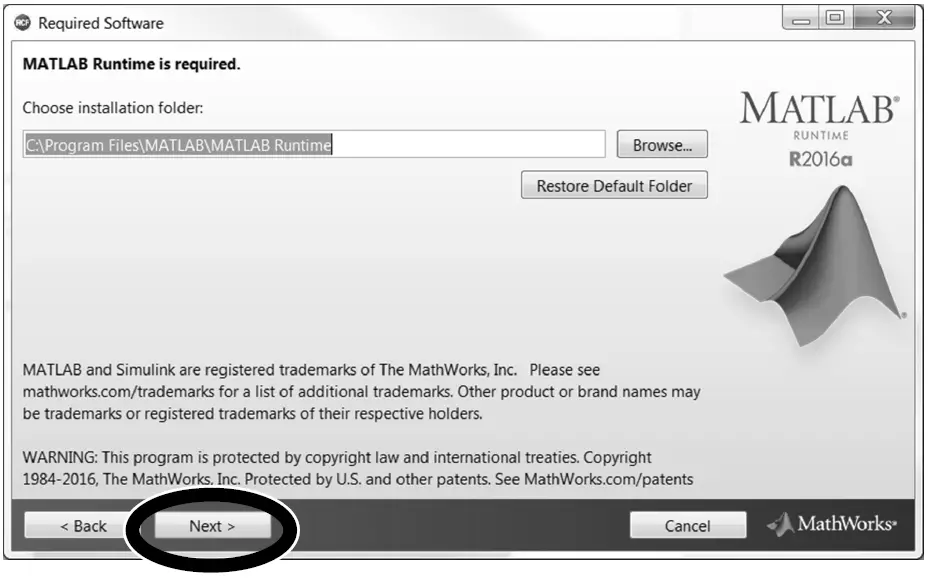

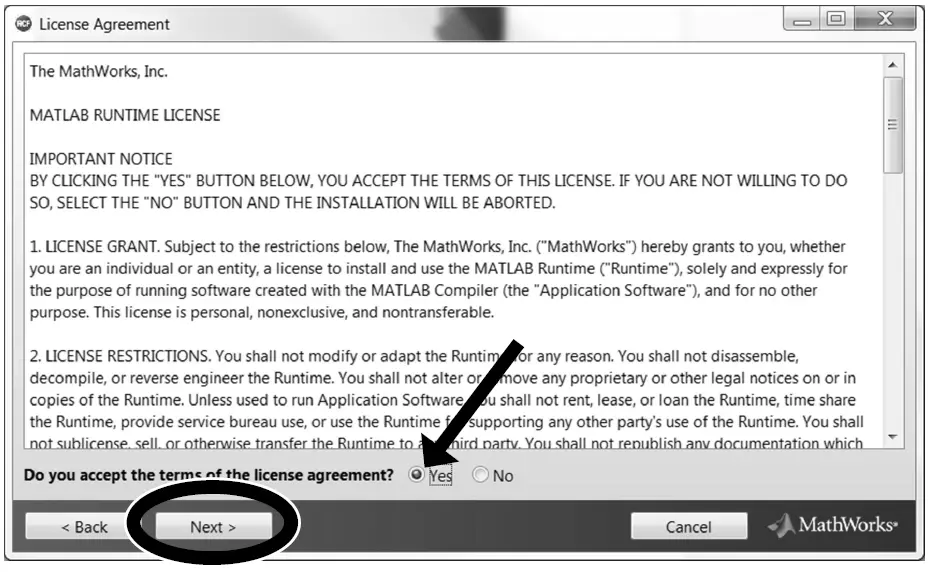

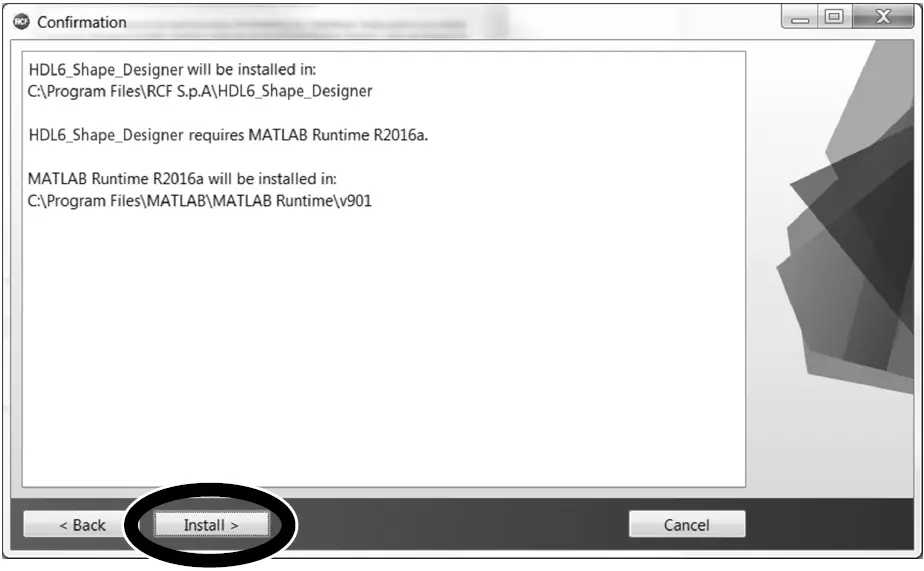

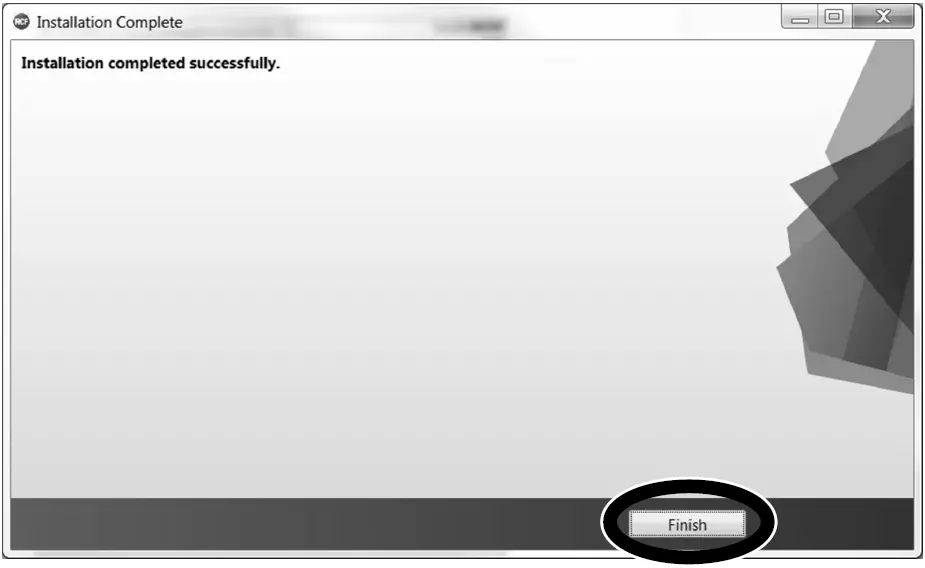

An haɓaka software ɗin tare da Matlab 2015b kuma yana buƙatar ɗakunan karatu na shirye-shiryen Matlab. A farkon shigarwa mai amfani yakamata ya koma zuwa kunshin shigarwa, samuwa daga RCF website, dauke da Matlab Runtime (ver. 9) ko kunshin shigarwa wanda zai sauke Runtime daga web. Da zarar an shigar da ɗakunan karatu daidai, ga duk nau'ikan software masu zuwa mai amfani zai iya saukar da aikace-aikacen kai tsaye ba tare da Runtime ba. Akwai nau'i biyu, 32-bit da 64-bit, don zazzagewa.

MUHIMMI:

- Matlab baya goyon bayan Windows XP don haka HDL50-ShapeDesigner (32-bit) baya aiki da wannan sigar OS.

- Kuna iya jira ƴan daƙiƙa kaɗan bayan danna sau biyu akan mai sakawa saboda software tana bincika idan akwai Laburaren Matlab. Bayan wannan mataki, shigarwa yana farawa. Danna mai sakawa na ƙarshe sau biyu (duba saki na ƙarshe a sashin saukewa na mu website) kuma bi matakai na gaba.

Bayan zaɓin manyan fayiloli don software na HDL6-SahpeDesigner (Hoto 2) da Matlab Libraries Runtime, mai sakawa yana ɗaukar mintuna kaɗan don tsarin shigarwa.

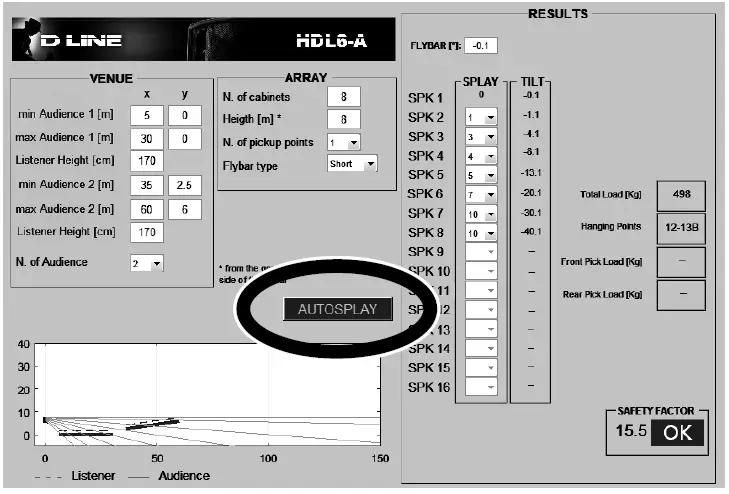

ZANIN TSARIN

- Software na HDL6 Shape Designer ya kasu kashi biyu na macro: ɓangaren hagu na dubawa an sadaukar da shi ga masu canji na ayyuka da bayanai (girman masu sauraro don rufewa, tsawo, adadin kayayyaki, da dai sauransu), ɓangaren dama yana nuna sakamakon aiki.

- Da farko mai amfani ya kamata ya gabatar da bayanan masu sauraro yana zaɓar menu mai dacewa da ya dace dangane da girman masu sauraro da kuma gabatar da bayanan lissafi. Hakanan yana yiwuwa a ayyana tsayin mai sauraro.

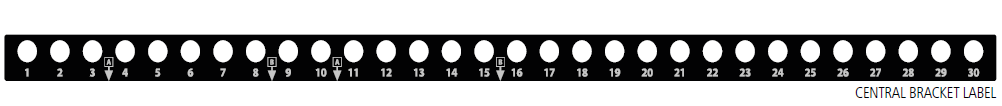

- Mataki na biyu shine ma'anar tsararrun zabar adadin kabad a cikin tsararru, tsayin rataye, adadin wuraren rataye da nau'ikan da ake samu na gardama. Lokacin zabar maki biyu masu rataye la'akari da waɗancan wuraren da aka sanya su a iyakar ƙwanƙwasa.

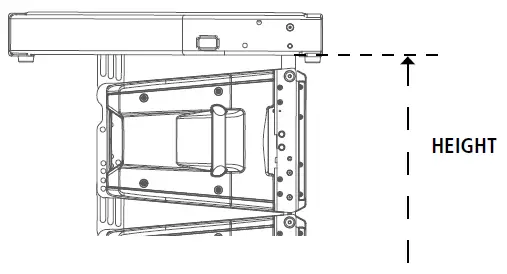

- Ya kamata a yi la'akari da tsayin jeri zuwa gefen ƙasa na jirgin sama, kamar yadda aka nuna a hoton da ke ƙasa.

Bayan shigar da duk bayanan da ke cikin ɓangaren hagu na mai amfani, ta danna maɓallin AUTOPLAY software zai yi:

- Wurin rataye don abin ɗauri tare da matsayi A ko B da aka nuna idan an zaɓi wurin ɗauka ɗaya, na baya da na gaba idan an zaɓi maki biyu.

- Flybar karkatar da kwana da majalisar splays (kusurwar da dole ne mu saita zuwa kowace majalisa kafin dagawa ayyuka).

- Ƙaunar da kowace majalisar za ta ɗauka (idan akwai wurin ɗauka ɗaya) ko kuma za mu ɗauka idan za mu karkatar da gungu tare da amfani da injuna biyu. (maki biyu karba).

- Jimlar nauyi da ƙididdige Factor na Tsaro: idan saitin da aka zaɓa bai bayar da Factor Safety> 1.5 saƙon rubutu yana nuna a cikin launi ja gazawar saduwa da ƙaramin yanayin aminci na injina.

Algorithm na wasan kwaikwayo na atomatik an ƙirƙira don mafi kyawun ɗaukar hoto na girman masu sauraro. Ana ba da shawarar yin amfani da wannan aikin don haɓaka tsararru. Algorithm mai maimaitawa yana zaɓar wa kowane majalisa mafi kyawun kusurwa da ke cikin injiniyoyi.

SHAWARAR GURIN AIKI

Da yake jiran software na siminti na hukuma da tabbataccen ƙima, RCF yana ba da shawarar yin amfani da HDL6 Shape Designer tare da Sauƙaƙe Mayar da hankali 3. Saboda buƙatar hulɗar tsakanin software daban-daban, aikin da aka ba da shawarar yana ɗaukar matakai masu zuwa don kowane tsararru a cikin aikin ƙarshe:

- Mai Zane Siffa: Masu sauraro da saitin tsararru. Ƙididdiga a cikin yanayin “autosplay” na karkatar da gardama, hukuma, da splays.

- Mayar da hankali 3: Ba da rahoto anan kusurwoyi, karkatar da sandar tashi, da saitattun abubuwan da Mai tsara Siffai ya ƙirƙira.

- Mai Zane Siffa: gyare-gyaren hannu na kusurwoyin splay idan simintin a cikin Mayar da hankali 3 bai ba da sakamako mai gamsarwa ba don bincika yanayin aminci.

- Mayar da hankali 3: Ba da rahoto anan sabbin kusurwoyi da karkatar da barnar gardama da Mai Zanen Siffai ya samar. Maimaita hanya har sai an sami sakamako mai kyau.

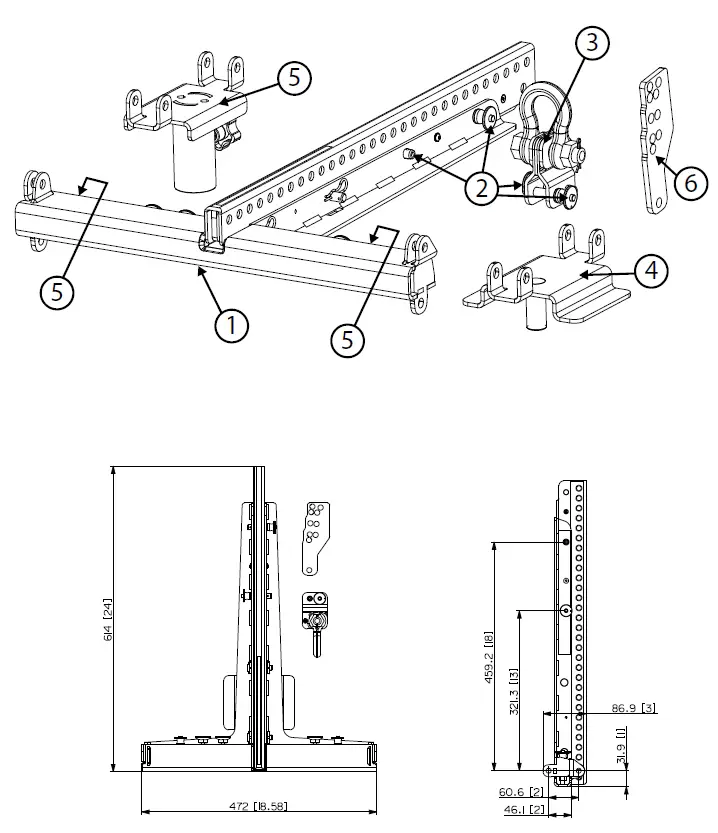

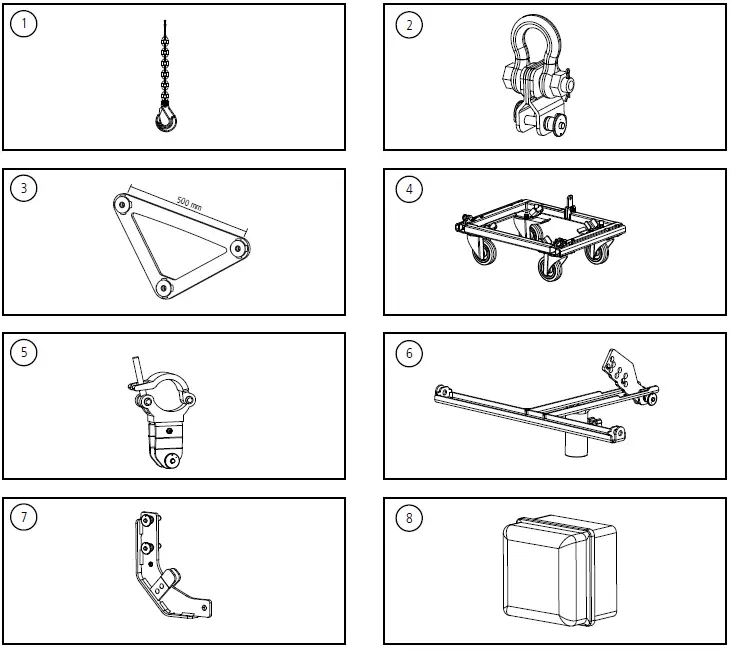

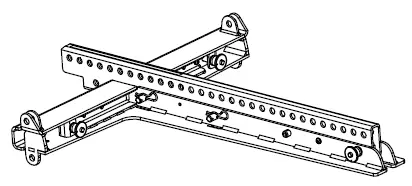

KAYAN RIGGING

| Bayani | Na'urorin haɗi p/n | |

| 1 | BARRA SOSPENSIONE HDL6-A E HDL12-AS

- har zuwa 16 HDL6-A - har zuwa 8 HDL12-AS - har zuwa 4 HDL12-AS + 8 HDL6-A |

13360360 |

| 2 | SAURAN KULLE PIN | 13360022 |

| 3 | FLY BAR DUBA HDL6-A | 13360372 |

| 4 | BANGASKIYA DOMIN KE TSAYE KULLE RUWAN CUTAR AKAN SUBWOOFER. | |

| 5 | BANGASKIYA DUNIYA |

| 1 | 13360129 | SARKIN TASARAR HALI. Yana ba da damar isashen sarari don rataya mafi yawan kwantenan sarkar motoci 2 kuma yana guje wa duk wani tasiri akan ma'auni na tsaye na tsararru lokacin da aka dakatar da shi daga wurin ɗauka guda ɗaya. |

| 2 | 13360372 | FLY BAR DUBA HDL6-A

+ 2 SAURAN LOCK PIN (SARE PART P/N 13360022) |

| 3 | 13360351 | AC 2X AZIMUT Plate. Yana ba da damar sarrafa manufa a kwance na tari. Dole ne a haɗa tsarin tare da motoci 3. 1 gaba da 2 haɗe zuwa farantin azimuth. |

| 4 | 13360366 | KART TARE DA KYAUTA AC KART HDL6

+ 2 SAURAN LOCK PIN (SARE PART 13360219) |

| 5 | 13360371 | Abubuwan da aka bayar na AC TRUSS CLAMP HDL6

+ 1 SAURAN LOCK PIN (SARE PART P/N 13360022) |

| 6 | 13360377 | Dutsen POLE 3X HDL 6-A

+ 1 SAURAN LOCK PIN (SARE PART 13360219) |

| 7 | 13360375 | LINKBAR HDL12 ZUWA HDL6

+ 2 SAURAN LOCK PIN (SARE PART 13360219) |

| 8 | 13360381 | RUWAN RUWA 06-01 |

HANYAR RIGGING

- Shigarwa da saitin ya kamata a yi ta ƙwararrun ma'aikata masu izini waɗanda ke kiyaye ingantattun Dokokin ƙasa don Rigakafin Hatsari (RPA).

- Yana da alhakin mutumin da ke shigar da taron don tabbatar da cewa wuraren dakatarwa / gyarawa sun dace da abin da aka yi nufi.

- Koyaushe gudanar da aikin dubawa na gani da aiki na abubuwan kafin amfani. Idan akwai shakku kan ingantaccen aiki da amincin abubuwan, dole ne a cire waɗannan daga amfani da sauri.

GARGADI

- Wayoyin karfen da ke tsakanin fitilun makullai na kabad da kayan aikin riging ba su da nufin ɗaukar kowane kaya. Dole ne kawai a ɗauki nauyin ma'auni ta hanyar haɗin gaba da Splay/Baya tare da na gaba da na baya na lasifika da firam ɗin Flying. Tabbatar cewa an shigar da dukkan fil ɗin kulle kuma an kulle su cikin aminci kafin ɗaga kowane kaya.

- A cikin misali na farko yi amfani da software na HDL 6-A Shape Designer don ƙididdige saitin tsarin da ya dace da kuma duba ma'aunin yanayin aminci.

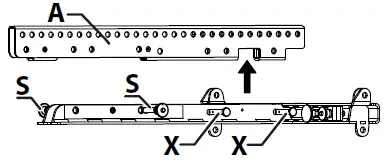

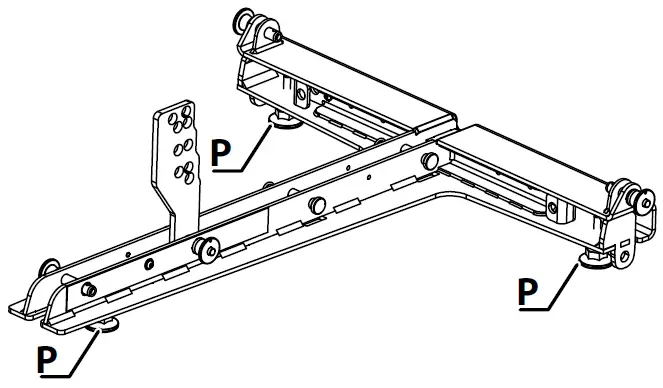

SANTA FLYBAR

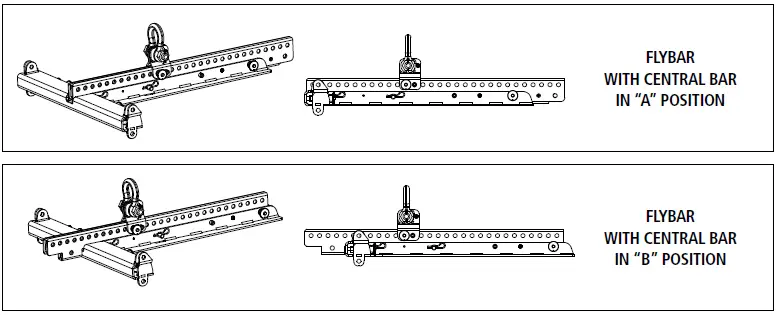

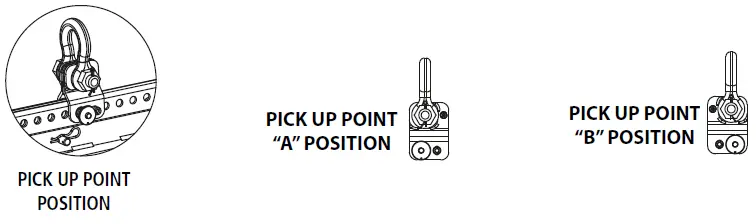

- HDL6 flybar yana ba da damar saita mashaya ta tsakiya a cikin jeri daban-daban guda biyu "A" da "B".

- Kanfigareshan “B” yana ba da damar mafi kyawun karkata na tari.

SATA TSAKIYAR TSARKI A MATSAYI "B".

Ana samar da wannan kayan haɗi a cikin tsarin "A".

Don saita shi a cikin tsarin "B":

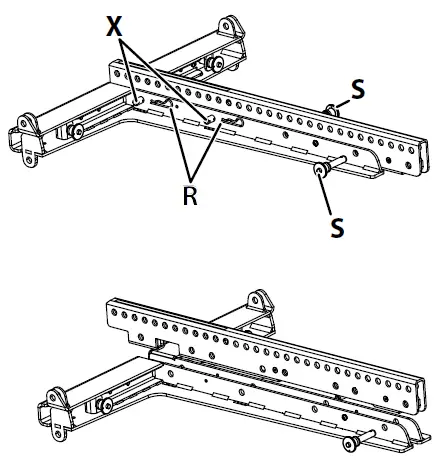

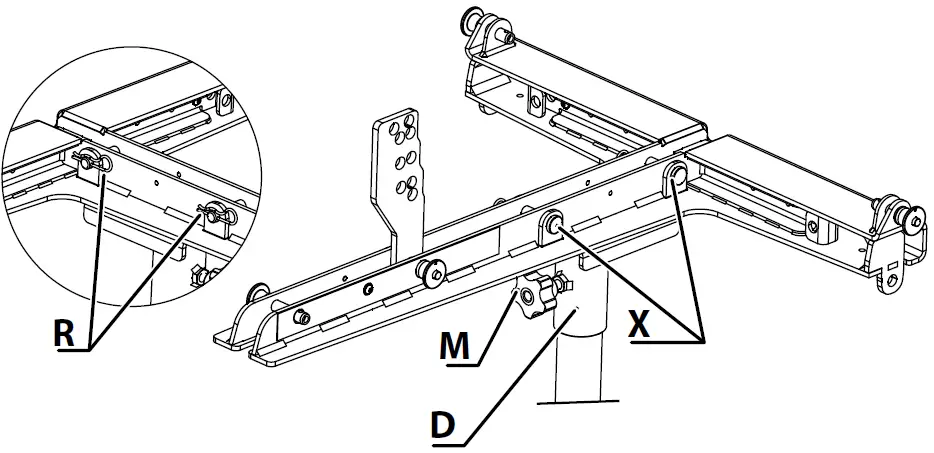

- Cire fil ɗin cotter ɗin “R”, ciro linchpins “X” da makullin makullin “S” da sauri.

- Ɗaga mashaya ta tsakiya sannan sake sanya shi yin nunin "B" akan lakabin kuma ramukan "S" sun dace tare.

- Sake haɗa ginshiƙan gardama yana maido da filayen “S”, da linchpins “X” da maƙallan “R”.

DUBA MATSAYI

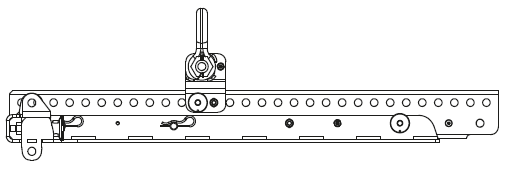

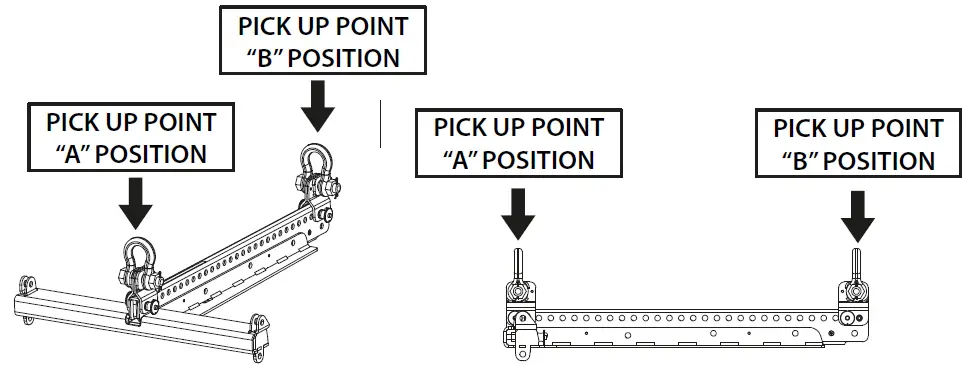

HANYAR DAKATA TSARIN

BAKIN DAYA GUDA DAYA

Sanya wurin ɗaukar gardama kamar yadda aka nuna a software, mutunta matsayin "A" ko "B".

DUAL PICK POINT

Yana ba da damar ɗaga gungu tare da jakunkuna biyu suna ƙara zaɓin zaɓi na zaɓi (pn 13360372).

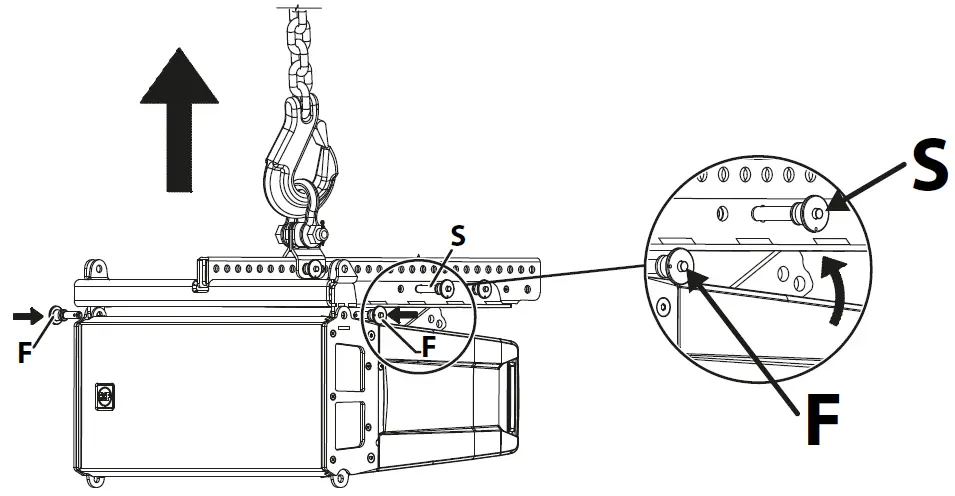

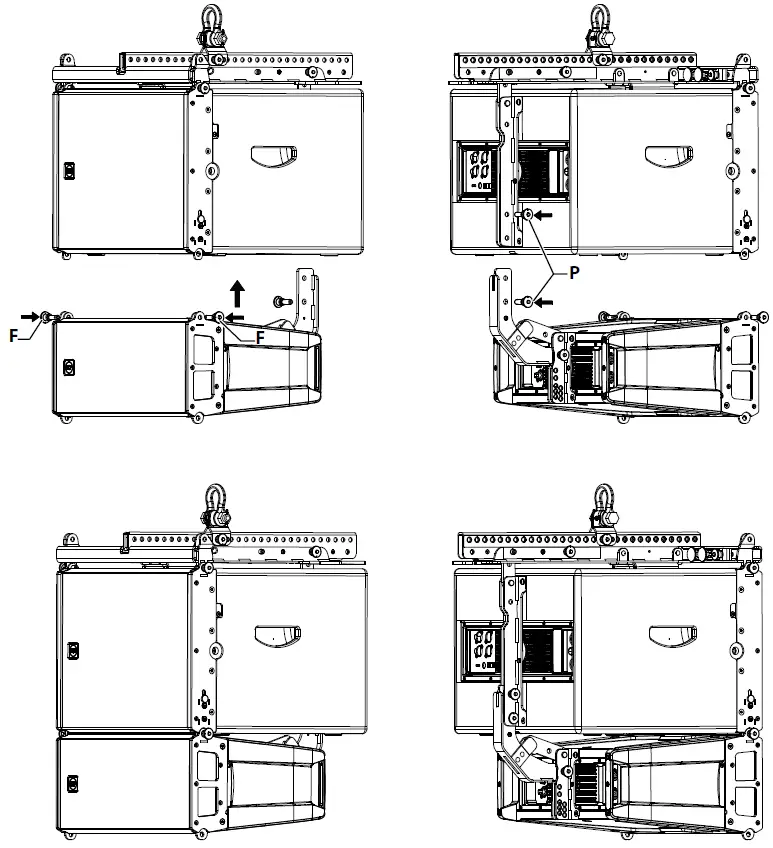

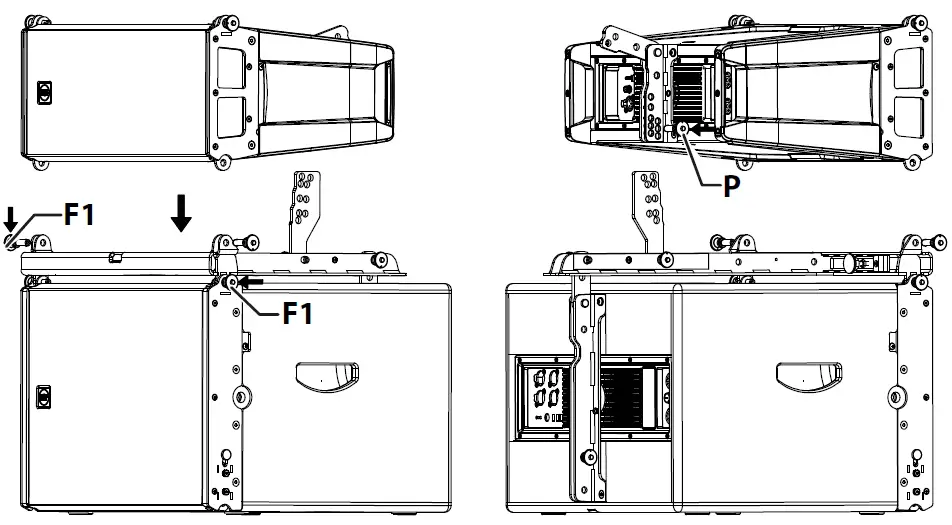

KARE FLYBAR ZUWA FARKO HDL6-A MAGANAR

- Saka maƙallan makulli na gaba "F"

- Juya madaidaicin baya kuma aminta dashi zuwa gadar tashi tare da maɓallin makulli mai sauri na baya "S" zuwa rami na HDL6 Link Point rami.

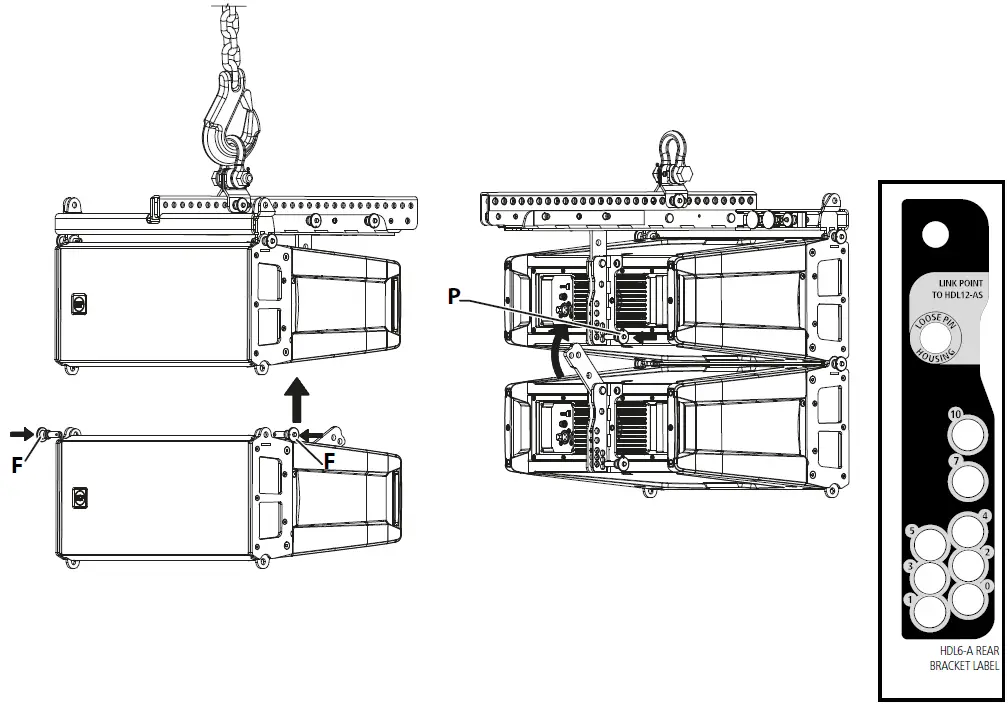

TSARE NA BIYU HDL6- MAI MAGANA ZUWA NA FARKO (kuma a jere)

- Kiyaye fil masu kulle-kulle na gaba "F"

- Juya madaidaicin baya kuma amintar da shi zuwa lasifikar farko ta amfani da fitin makulli mai sauri na baya “P”, zaɓi kusurwar karkarwa kamar yadda aka nuna akan software.

KARE FLYBAR ZUWA FARKO HDL12-ASKE MAGANA

- Saka maƙallan makulli na gaba "F"

- Juya madaidaicin baya kuma aminta dashi zuwa gadar tashi tare da maɓallin makulli mai sauri na baya "S" akan rami na HDL12 Link Point.

TSARE NA BIYU HDL12-A MATSAYIN MAI MAGANA ZUWA NA FARKO (kuma a jere):

- Cire sashin gaba "A"

- Tsare madaidaicin makulli na gaba "F"

- Juya madaidaicin baya kuma amintar da shi zuwa lasifikar farko ta amfani da fitin makulli mai sauri na baya "P".

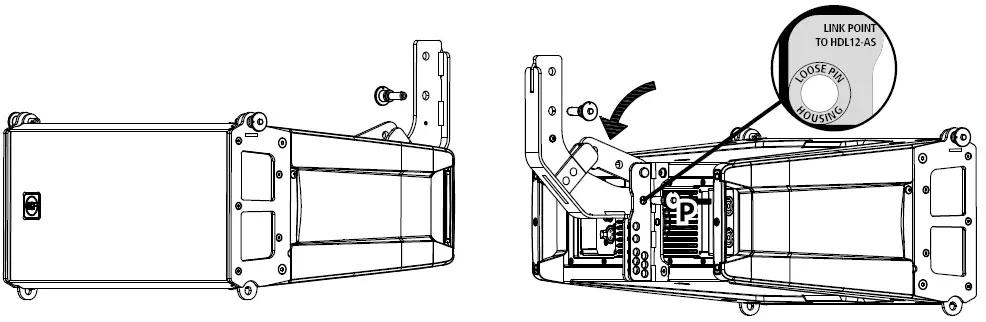

CLUSTER HDL12-AS + HDL6-A

- Yin amfani da fil ɗin makulli mai sauri “P”, amintar da haɗin haɗin gwiwa zuwa HDL6-A mai magana akan ramin “Link point to HDL12-AS”, akan sashin baya.

- Juya madaidaicin HDL6-A na baya kuma toshe shi akan madaidaicin haɗin tsakanin ɓangarorin ƙarfe biyu.

- Amintacce HDL6-A zuwa HDL12-AS ta amfani da fitattun makullai na gaba "F" da na baya "P".

GARGADI:

ko da yaushe amintattu biyu na baya fil"P".

HANYAR TSARO

Cire mashaya ta tsakiya "A" daga mashigar gardama ta hanyar zare linchpins "X" da makullin makullin "S".

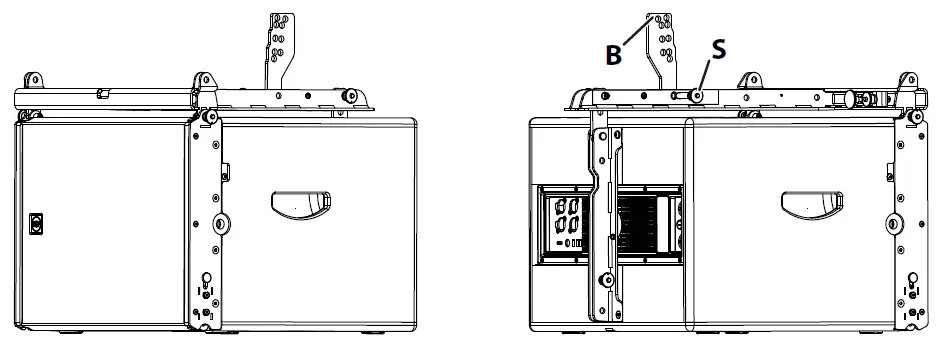

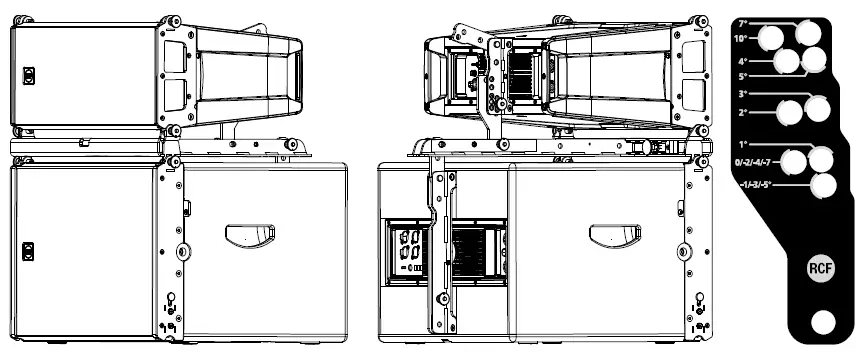

TSARKI AKAN SUB HDL12-AS

- Tsare mashigar tashi zuwa HDL12-AS

- Tsare mashigin “B” (kamar yadda aka nuna a hoto) zuwa gadar tashi ta amfani da madaidaicin makulli mai sauri “S” (bi alamar “stacking point”)

- Amintacce HDL6-A zuwa gadar gardama ta amfani da fitin makulli na gaba "F1".

- Zaɓi kusurwar karkarwa (kusurwoyi masu kyau suna nuna ƙaramin karkata na lasifikar) kuma amintar da shi tare da maɓallin kulle mai sauri na baya "P".

Don samun karkatawar lasifikar (tabbatacce ko mara kyau) kuna buƙatar daidaita ƙimar kusurwar sandar stacking tare da ƙimar kwana ɗaya da aka bayyana akan maƙallan baya na lasifikar.

Wannan hanyar tana aiki ga kowane karkata sai dai kusurwoyi na 10 da 7 na sandar stacking, wanda don haka kuna buƙatar ci gaba ta hanya mai zuwa:

- kwana 10 na sandar tarawa yana buƙatar daidaitawa tare da kusurwa 0 akan sashin baya na lasifikar.

- kwana 7 na sandar tarawa yana buƙatar daidaitawa tare da kusurwa 5 akan sashin baya na lasifikar.

GARGADI:

KOYAUSHE TABBATAR DA TSINTSIN TSARI A CIKIN KOWANE SIRRI

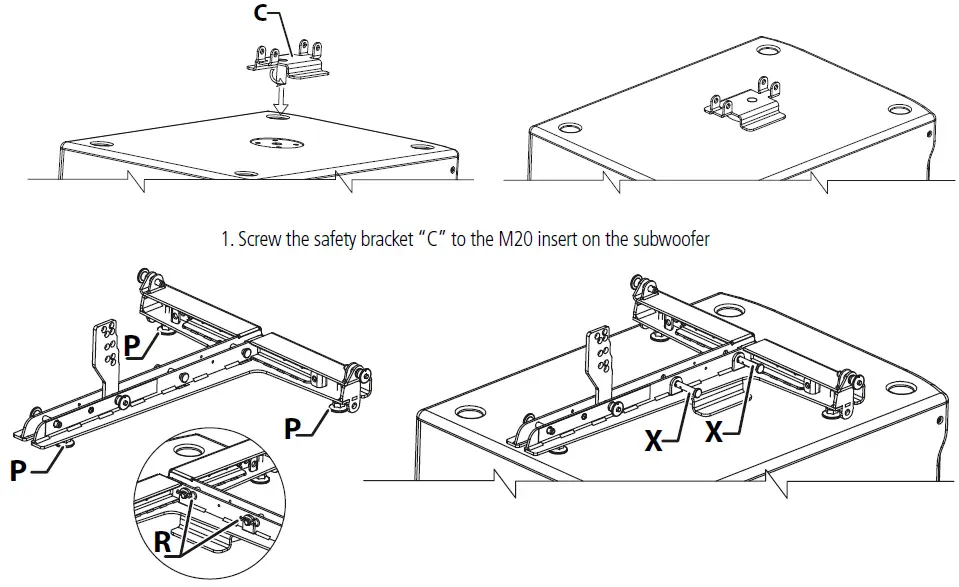

TSAKI AKAN SUBWOOFERS DABAN (WANDA HDL12-AS)

- Cire duk ƙafafu na filastik "P".

- Tsare shingen gardama zuwa madaidaicin aminci ta amfani da linchpins “X” kuma ka toshe su tare da tarkace “R”.

- Daidaita ƙafafu don daidaita shingen gardama a kan subwoofer sannan a toshe su da goro don guje wa kwancewa.

- Haɗa lasifikar HDL6-A tare da hanya iri ɗaya.

GARGADI:

KOYAUSHE TABBATAR DA TSINTSIN TSARI A CIKIN KOWANE SIRRI

GASKIYAR TSARO

- Cire duk ƙafafu na filastik "P".

- Daidaita ƙafafu don daidaita ma'aunin gardama a kan subwoofer sannan a toshe su da ƙwaya don guje wa kwancewa.

- Haɗa lasifikar HDL6-A tare da hanya iri ɗaya.

GARGADI: KOYAUSHE TABBATAR DA TSINTSIN TSARI A CIKIN KOWANE SIRRI

DOGARO DA POLE TARE DA KARYA

- Ajiye madaidaicin dutsen sandar zuwa gadar gardama tare da linchpins “X” sannan a toshe su da fitilun “R”

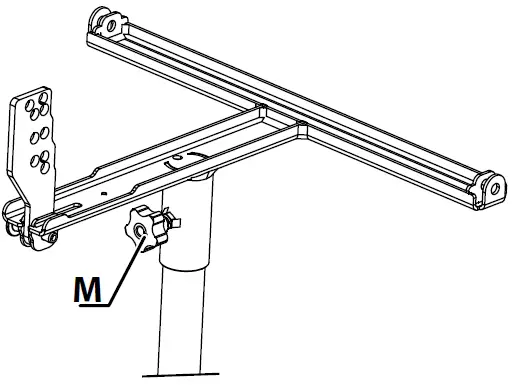

- Toshe mashin gardama zuwa sandar ta hanyar dunƙule ƙulli "M".

- Haɗa lasifikar HDL6-A tare da hanya iri ɗaya.

GARGADI: KADA KA TABBATAR

- TSARIN TSARI A CIKIN KOWANE TSARIN

- KYAUTA POLE

MAGANAR POLE TARE DA DUMIN POLY 3X HDL 6-A

- Tsare shingen gardama akan sandar ta hanyar dunƙule ƙulli "M"

- Haɗa masu magana HDL6-A tare da hanya iri ɗaya da aka yi amfani da ita akan tari akan sub-HDL12-AS

GARGADI: KADA KA TABBATAR

- TSARIN TSARI A CIKIN KOWANE TSARIN

- KYAUTA POLE

MOTSA:

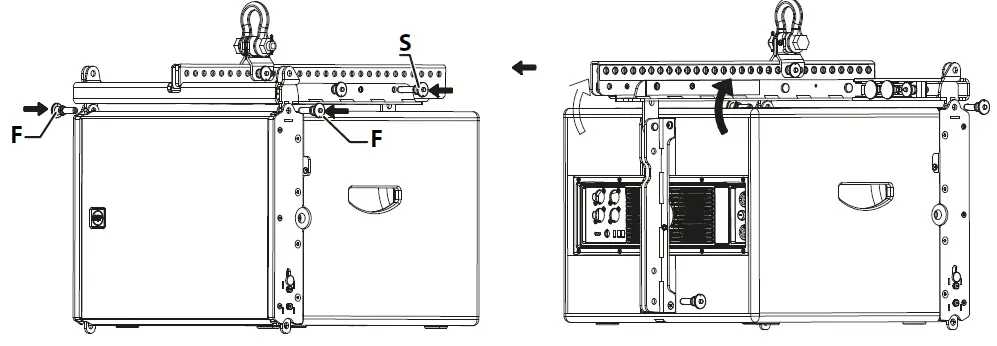

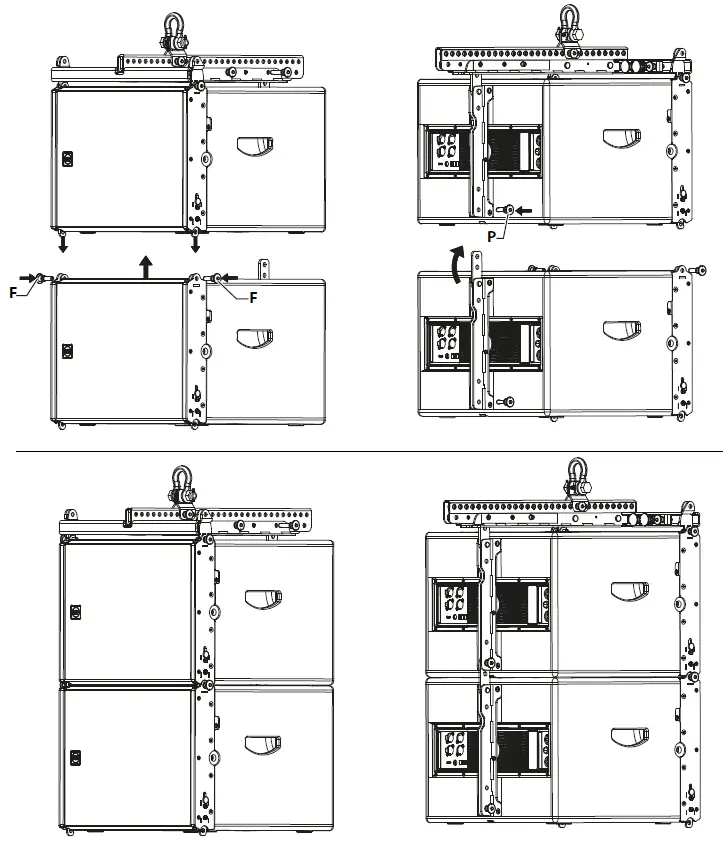

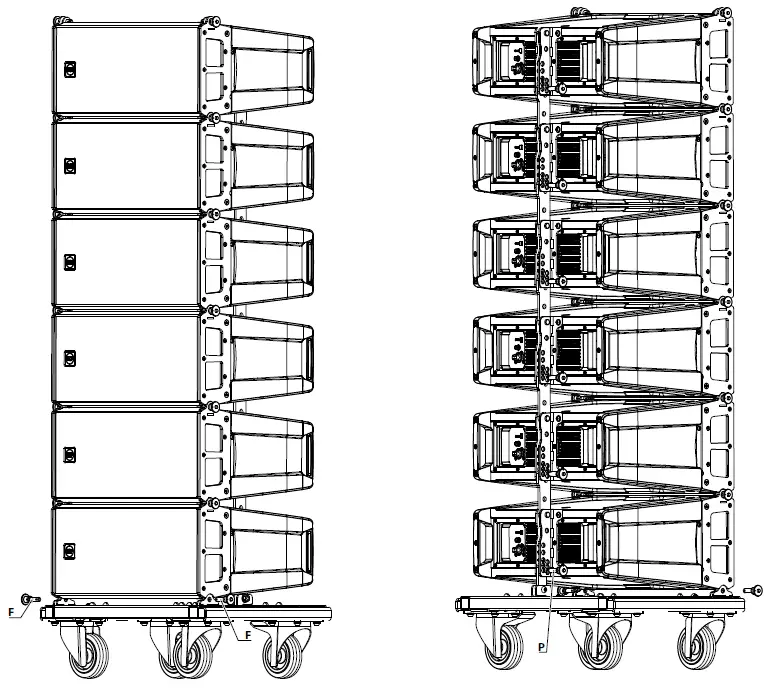

SANAR DA MAGANAR KAN KART.

- Tsare gefen gaba na lasifikar zuwa kart ta amfani da makullin makulli mai sauri "F"

- Kiyaye gefen baya na lasifikar zuwa kart ta amfani da makullin kulle mai sauri "P".

A hankali: ramin da za a yi amfani da shi shine 0° akan mashin baya na lasifikar. - Ci gaba da mai magana na biyu yana maimaita matakai "1" da "2"

GARGADI:

An ƙera kart ɗin don ɗaukar har zuwa masu magana guda 6.

KULA DA KIYAYE

KASHE

TRANSPORT - KYAUTA

- A lokacin sufuri tabbatar da abubuwan da aka gyara ba su da damuwa ko lalacewa ta hanyar sojojin inji. Yi amfani da abubuwan sufuri masu dacewa. Muna ba da shawarar amfani da kart ɗin yawon shakatawa na RCF HDL6-A don wannan dalili.

- Saboda maganin saman su, kayan aikin riging suna kariya na ɗan lokaci daga danshi. Koyaya, tabbatar da abubuwan haɗin suna cikin bushewa yayin adanawa ko lokacin sufuri da amfani.

KA'idodin aminci - HDL6-A KART

- Kada ku tara fiye da HDL6-A shida akan Kart ɗaya.

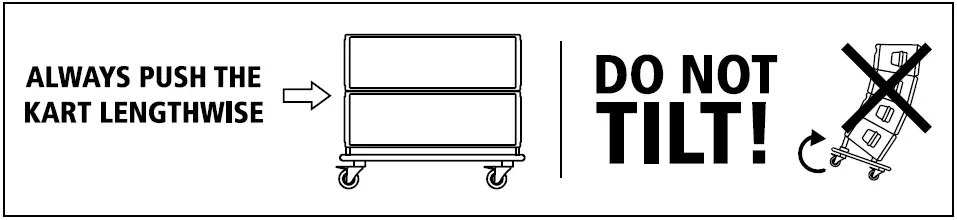

- Yi taka tsantsan yayin motsi tarin akwatuna shida tare da Kart don guje wa tipping.

- Kada a matsar da tari a gaban-zuwa-baya na HDL6-A's (gefe mai tsayi); ko da yaushe matsar da tari gefe don kauce wa tipping.

BAYANI

HDL 6-A/HDL 12-AS

- Martanin Mitar 65 Hz - 20 kHz 40 Hz - 120 kHz

- Max Spl 131 dB 131 dB

- Hannun Rufe A kwance 100° –

- Matsayin Rufe A tsaye 10° –

- Direban matsawa 1.0" neo, 1.7"vc -

- Woofer 2 x 6.0" neo, 2.0"vc 12", 3.0"vc

Bayani

- Mai Haɗin shigarwa XLR namiji Stereo XLR

- Mai Haɗin Fitarwa XLR mata Stereo XLR

- Sensitivity + 4 dBu – 2 dBu/+ 4 dBu

PROCESSOR

- Mitar Crossover 900 Hz 80-110 Hz

- Kariya Thermal, RMS Thermal, RMS

- Mai iyaka Soft iyakance Soft iyakance

- Yana sarrafa ƙarar gyaran HF, EQ, lokaci, xover

AMPRAYUWA

- Jimlar Ƙarfin 1400 W Peak 1400 W Peak

- Babban Mitoci 400 W Peak -

- Ƙananan Mitoci 1000 W Ƙwararru -

- Sanyi convection convection

- Connections Powercon in-out Powercon in-out

BAYANI NA JIKI

- Tsawo 237 mm (9.3 ") 379 mm (14.9")

- Nisa 470 mm (18.7 ") 470 mm (18.50")

- Zurfin 377 mm (15 ") 508 mm (20")

- Nauyi 11.5 Kg (25.35 lbs) 24 Kg (lbs 52.9)

- Haɗin Majalisar PP Baltic Birch Plywood

- Hardware Integrated makanikai Array fittings, sandar sanda

- Hannu 2 baya 2 gefe

RCF SpA:

Ta Raffaello, 13 – 42124 Reggio Emilia – Italiya tel. +39 0522 274411 - fax +39 0522 274484 - e-mail: rcfservice@rcf.it. www.rcf.it.

Takardu / Albarkatu

|

RCF HDL 6-A Layin Array Module [pdf] Littafin Mai shi HDL 6-A, HDL 12-AS, HDL 6-A Module Array Module, HDL 6-A, Module Array Module, Module Array, Module |